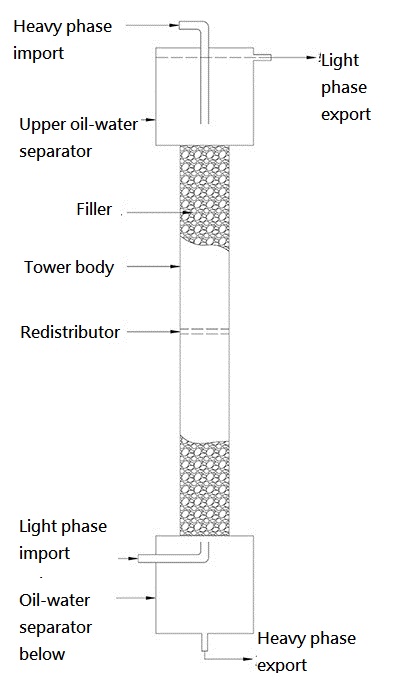

Packed extraction tower

Equipment Introduction

A packed extraction tower is a tower-type device used in liquid-liquid extraction processes. It achieves sufficient contact and mass transfer between two phases (light and heavy phases) through a packing layer, thereby separating and enriching the target components. It has a simple structure, flexible operation, and is widely used in chemical, petroleum, pharmaceutical, and environmental protection fields.

Tower extraction equipment features small footprint, large processing capacity, and good sealing performance. Different structures can be designed according to separation requirements, processing capacity, and system characteristics.

Commonly used extraction towers include packed extraction towers, rotary disc extraction towers, turbine extraction towers, and vibrating sieve plate towers.

Packed Extraction Towers

Packed towers are gravity dispersion extraction towers. The tower is filled with packing material. The light phase enters from the bottom and flows out from the top, while the heavy phase flows in from the top and flows out from the bottom. During the flow, the two phase droplets are dispersed and collided by the packing material, thus achieving mass transfer. Commonly used packing materials include Raschig rings, saddle rings, and Pall rings.

Notes

- Tower diameter and height can be customized according to requirements;

- Commonly used materials include PMMA, transparent PVC, high borosilicate glass, stainless steel, etc.

繁體中文

繁體中文 简体中文

简体中文