Mixer-Settler Extractor

Equipment Introduction

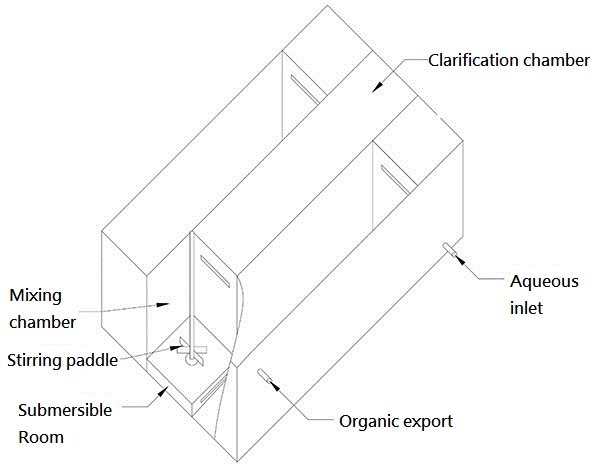

The Mixer-Settler Extractor is widely used for the separation and purification of metals in the solvent extraction process of hydrometallurgy. It consists of a continuously fed and stirred mixing chamber and a settling chamber where gravity causes the mixed liquid to separate into phases.

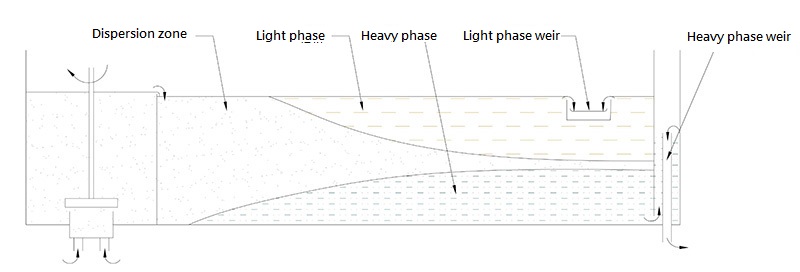

In practice, multi-stage series configurations are often used to achieve deep separation of the target analyte. Under certain process conditions, the mass transfer efficiency of the mixing chamber is related to the mixing intensity of the agitator and the contact time between the two phases, while the settling effect is related to the viscosity, density, surface tension, droplet diameter, settling area, and settling time of the two phases.

Structural diagram

Working Process

Mixing and Mass Transfer Process:

The extractant and feed liquid enter the submersible chamber or manifold from the bottom of the extraction tank in a certain proportion. They are then drawn into the mixing chamber by a wheel-type agitator and sheared and mixed to disperse them. At this time, the two liquid phases are fully mixed, allowing the solute to be transferred from one liquid phase to the other, thus completing the mixing and mass transfer process.

Separation process:

The mixture overflows from the mixing chamber to the settling chamber. Due to the difference in density between the two phases, they are separated under the action of gravity. The separated liquids flow out through the light and heavy phase weirs or enter the next stage.

Features

♦ Simple Structure: The extraction tank generally consists of a tank body, interface regulating pipe, motor reducer, stirring shaft, stirring paddle, speed controller, and movable platform, resulting in a relatively simple structure.

♦ Stable Operation and Strong Adaptability: Due to its large volume and high liquid capacity, the extraction tank can adapt to fluctuations in the liquid level within a certain range. After adjustment and balancing, its operation is relatively stable and highly adaptable.

♦ Reliable Scale-Up: The design parameters, such as the extraction rate of a single stage, remain relatively reliable even after scale-up.

Application Areas

Copper Extraction

Rare Earth Extraction and Separation

Nickel-Cobalt Extraction

Rare and Precious Metal Extraction

Nuclear Industry

6-Level Mixer-Settler Extractor

9-Level Mixer-Settler Extractor

繁體中文

繁體中文 简体中文

简体中文