Centrifugal extractor

Equipment Introduction

A centrifugal extractor is a new type of rapid and efficient liquid-liquid extraction and separation equipment. It offers higher separation efficiency than traditional extraction equipment such as extraction tanks and extraction towers, and is more conducive to continuous production.

The centrifugal extractor utilizes a motor to drive a high-speed rotating drum. The two liquids to be mixed and separated undergo mass transfer under the shear force generated by the stirring paddle, and then are rapidly separated under the centrifugal force generated by the high-speed rotation of the drum.

Centrifugal extractors can be used individually or in series to achieve countercurrent extraction. They offer high mass transfer efficiency, short two-phase residence time, low retention, and are easy to operate. The rotation speed, flow ratio, and mixing intensity can be adjusted as needed.

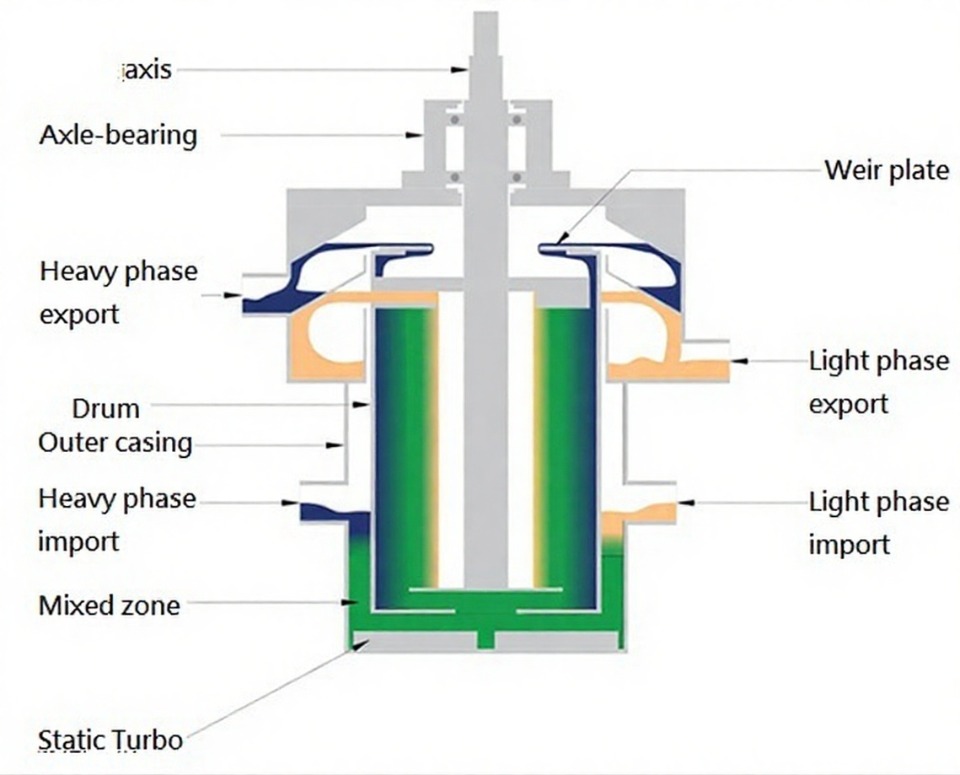

Schematic diagram of LC series centrifugal extractor

Working Process

Mixing and Mass Transfer Process

Light and heavy phase solutions enter the mixing chamber through two separate feed inlets in a specific ratio. Under the action of the stirring paddle, the mixing and mass transfer process is rapidly completed.

Two-Phase Separation Process

The mixture enters the rotating drum under the action of a static turbine. Within the cavity formed by the web, the mixture quickly rotates synchronously with the drum. Under the action of centrifugal force, the denser heavy phase gradually moves away from the center of the drum and towards the drum wall as it flows upwards; the less dense light phase gradually moves away from the drum wall and towards the center. The clarified two phases finally enter the collection chamber through their respective channels and flow out tangentially in a square pattern, completing the two-phase separation process.

Equipment Features

♦ Simple and stable structure: Top-suspended structure, no bottom bearing, no risk of leakage;

♦ High extraction efficiency: Independent mixing chamber, the agitator can be replaced according to the mixing system requirements;

♦ Energy saving: Non-annular gap mixing structure, the drum itself does not participate in mixing, low energy consumption and effectively avoids emulsification caused by overmixing;

♦ Corrosion resistance: Materials can be stainless steel or non-metallic composite materials;

♦ Good sealing performance: Multi-stage shaft seal design, magnetic drive structure is also optional.

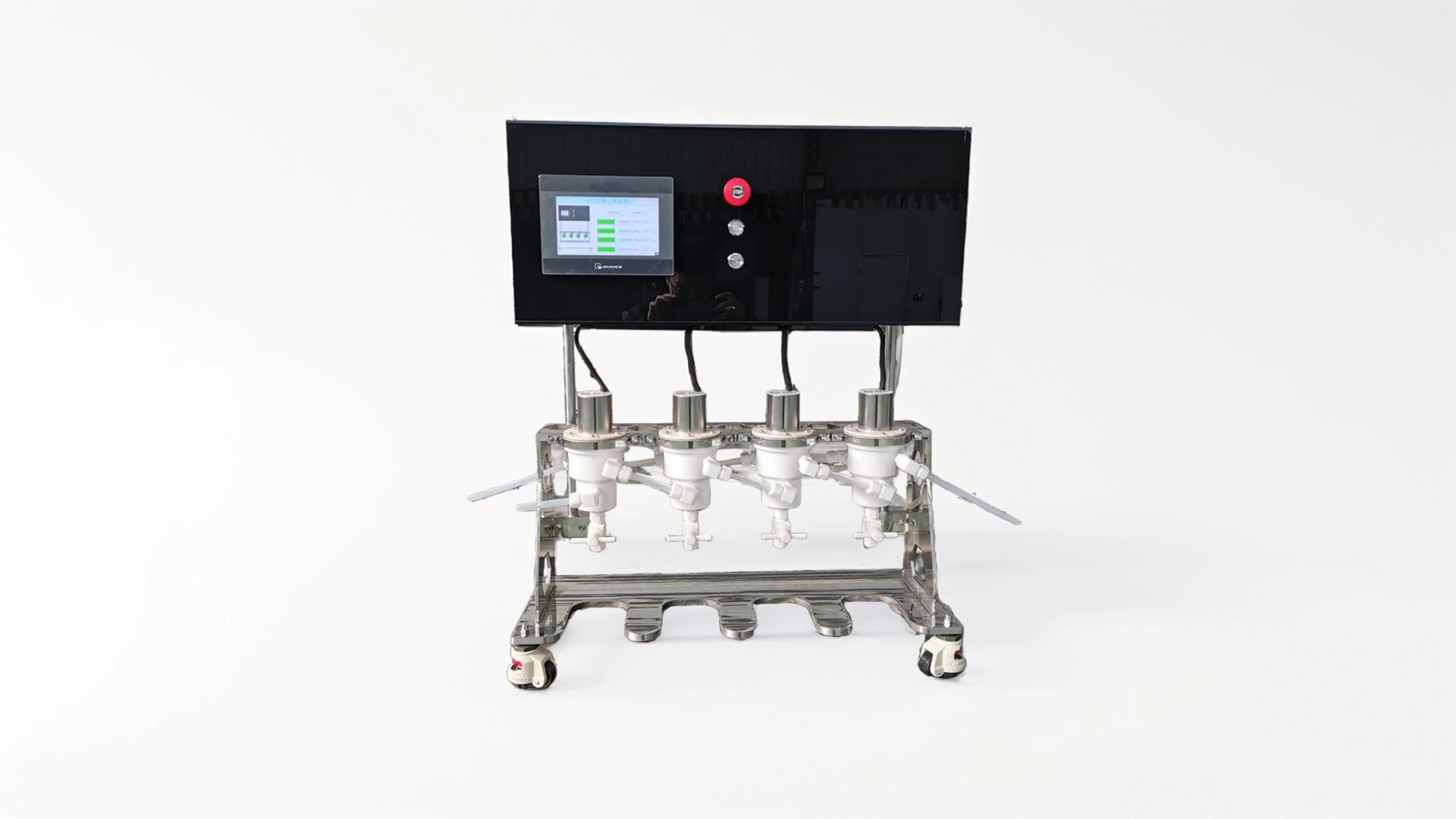

LC-50 Experimental Multistage Centrifugal Extractor

繁體中文

繁體中文 简体中文

简体中文